Laminar Air Flow Systems Explained

Laminar Air Flow Systems – General Terminology

Laminar air flow principles and Laminar air flow systems are commonly used in cleanrooms, positive and negative pressure rooms and other sensitive controlled environments. The best way to understand laminar air flow is to first differentiate between laminar air flow as a principle and laminar air flow in use as a system.

Laminar air flow: principle – Laminar air flow is a process where air is manipulated to force air to move at the same speed and in the same direction, with no or minimal cross-over of air streams in a given space.

“In laminar flow, the motion of the particles of the fluid is very orderly with particles close to a solid surface moving in straight lines parallel to that surface. Laminar flow is a flow regime characterized by high momentum diffusion and low momentum convection.” – Wikipedia

Laminar air flow systems – these are mechanical systems manufactured to provide laminar air flow in a large or small area to perform certain tasks in an environment of constant non-turbulent air flow.

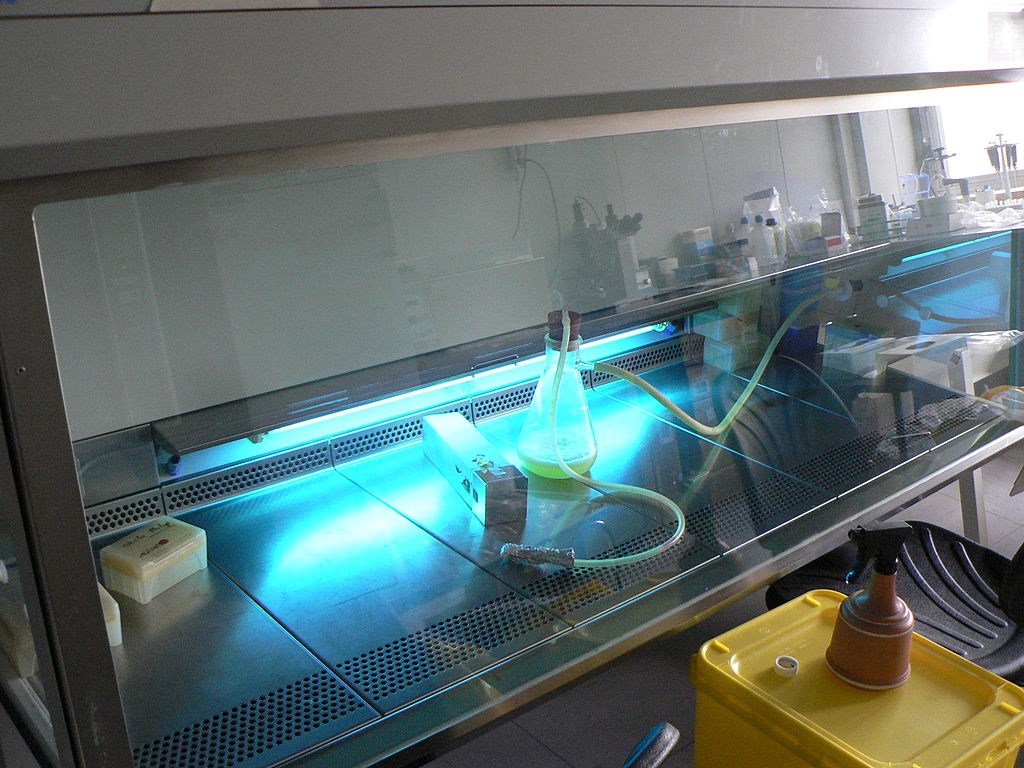

Laminar air flow systems are usually cabinet-based, but may be designed to be a booth or work bench or even a room as well. Some common designs are:

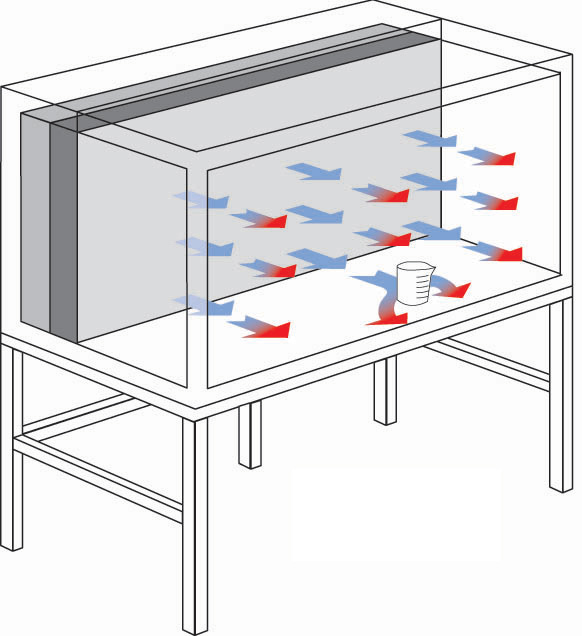

- Vertical Laminar Flow Cabinets – Vertical Laminar Flow Cabinets function much like horizontal Laminar Flow Cabinets, however, in vertical setups the laminar air is directed vertically downwards onto the working area. The air can leave the working area via holes in the base. Vertical flow cabinets typically provide more protection for the booth/cabinet operator because the air can be directed away from the operator.

- Horizontal Laminar Flow Cabinets – Horizontal Laminar Flow Cabinets where air flow originates from above the work area but then changes direction and is processed across the work area in a horizontal direction. The constant flow of filtered air provides material and product protection.

- Laminar Flow Cabinets and Hoods – these are the housings manufactured to create the controlled air environment.

- Laminar Flow Benches and Booths – these are larger designs; typically designed for larger manufacturing processes.

Laminar air flow stations are built with respect to the type of process being performed. There are times when maintaining a very high level of cleanliness is desired, so a laminar air flow cabinet or bench may reside inside an existing cleanroom. Other times, a cabinet may be a standalone design in a facility without a cleanroom at all.

Laminar Flow Cabinets are typically designed to protect the working area only. They do not offer operator protection and are not suitable for working with bio-hazards.

Laminar Air Flow System Types and Uses

Depending on the goals of the company and operator of a laminar air flow system, there will exist certain “pro’s” and “con’s” of using one type over another. in fact, many larger facilities will take advantage of using both types.

Vertical Laminar Air Flow Systems

Let’s first look at some pros and cons of using a vertical laminar air flow system.

Pro’s

- The hood/unit is not as deep as horizontal units, and thereby requires less floor space.

- Best choice for compounding sterile products, consumables and pharmaceuticals.

- Safer because the controlled air is not blowing directly towards operator, standard sash provides barrier between process and operator’s face.

- The filter unit is located on top; which makes it easier to change without technical intervention.

- Typically has less turbulent effects from air striking larger objects and equipment.

- Less of a chance of cross-contamination between items positioned on the work surface.

Con’s

- While filters are easy to access, most systems require a generous overhead clearance; changing filters or servicing unit may require a step-ladder and altered construction to provide ample overhead clearance.

- Cannot place items (or hands) on top of other items: because or possible airflow obstruction.

- Potential for increased turbulent effect at the work surface because of air striking the work surface.

Horizontal Laminar Air Flow Systems

Now, let’s take a look at some pros and cons of using horizontal laminar air flow systems:

Pro’s

- Greatly reduced turbulent effect of air striking the primary work surface space.

- No sash: may make it easier to work and position equipment.

- Hands and gloves are generally less contaminating since they’re downstream of the primary work-space.

Con’s

- Changing the filter and/or servicing the unit requires the hood be removed/re-positioned and may require technical expertise.

- Large samples/objects may obstruct laminar air flow, and this may contaminate downstream objects.

- Horizontal flow blows fumes and/or particles in operator’s face.

In addition to the primary differences in functionality and operation of both vertical and horizontal laminar air flow systems there are many sub-types of hoods and booths that may fall under each primary type. These may include:

- Explosion proof laminar air flow systems

- Biological protection laminar air flow systems

- Ductless exhaust fume protection laminar air flow systems

- Biomedical laminar air flow systems

- Free-standing, portable, and built-in units

- Units with high heat, or UV exposure

- Clean benches

As a note of caution, neither vertical or horizontal laminar flow hoods are appropriate when operating in conditions where bio-hazards are present. Work with bio-hazards should only be carried out in an approved containment area. One such cabinet is a Class II, Type A2 Biosafety Cabinet; used in applications requiring Biosafety Level (BSL) 2 or 3 containment rating.

In essence, a laminar air flow system is a way of creating an ultra-clean work-space and environment for manufacturing a specific part of a larger process, or compounding a consumable/pharmaceutical compound. In a cleanroom or typical controlled air environment, there are too many factors that would negatively affect the process – the primary one being turbulence that can disturb processes on a microscopic level. Cleanrooms and controlled air environments can, in addition to improving the purity of a product, also protect operators and the general public.

Clean ratings for laminar flow systems, typically measured as an ISO class, varies, just as the rooms they are physically located in.

A large part of being able to control the environment inside of any laminar air flow system is the ability to control and monitor temperature, differential air pressure and relative humidity. Most modern units are manufactured with constant monitoring systems built-in to the laminar air flow unit. However, this is but one monitoring system. The drawback is potential instrument failure, and the fact that the builder of the laminar air flow system specializes in air flow, not necessarily in the monitoring and reporting of actual air conditions.

Many manufacturers of laminar air flow systems are turning to expert instrument manufacturers and creating OEM-based instrument inclusions. Some operators are sourcing secondary monitoring and alerting systems irrespective of the laminar air system manufacturer for additional protection. After all, the operator stands to lose the most in terms of product efficacy, safety and operator safety.