Prevent Contamination in Negative Pressure Rooms

A positive pressure room maintains a positive air flow to force particles and contaminants out when opened. A positive pressure room is sealed effectively, and specially designed HVAC systems are usually installed to keep the room pressurized. Additional HEPA filters may be added to the positive pressure room to maintain an extremely low particle and contamination count for hospitals, pharmacies and highly sensitive manufacturing processes. Hospitals may also utilize a positive pressure room or cleanroom to maintain patient safety; as positive pressure in hospital rooms keeps bacteria and other harmful contaminants away from the patient.

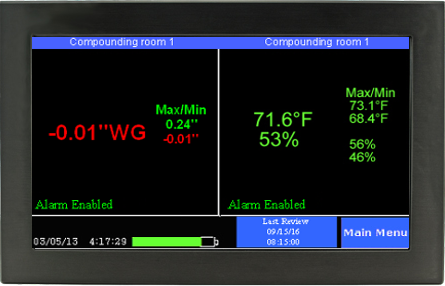

The TV2 Monitor accurately reports pressure, temperature and relative humidity conditions in positive pressure rooms for:

- USP/Pharmaceutical positive pressure rooms

- Hospital positive pressure and isolation rooms

- Laboratory positive pressure and isolation rooms

- CDC Positive Pressure Isolation Rooms

- Airborne Infection Isolation Rooms (AIIS)

- USP 797 Compounding Pharmaceutical Cleanrooms

- USP 800 Compounding Pharmaceutical Cleanrooms

- Manufacturing process positive/negative pressure cleanrooms

- General use/ISO/USP Cleanrooms

The TV2 Cleanroom Monitor meets all ISO and USP Standards

| ISO 1 Cleanroom |

ISO 2 Cleanroom |

ISO 3 Cleanroom |

| ISO 4 Cleanroom |

ISO 5 Cleanroom |

ISO 6 Cleanroom |

| ISO 7 Cleanroom |

ISO 8 Cleanroom |

ISO 9 Cleanroom |

*Includes Class 1 Cleanroom, Class 2 Cleanroom, Class 3 Cleanroom, Class 4 Cleanroom